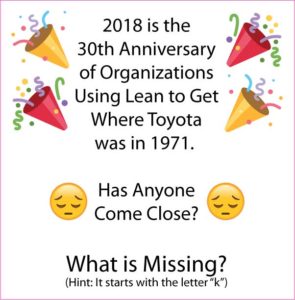

Is Lean thinking the same as kaizen thinking?

Kaizen thinking is a unique way of thinking that is learned when one participates in Toyota-style kaizen. This type of kaizen is rooted in industrial engineering (IE) methods and is practiced for the purpose of improving productivity, with a goal of reducing cost (where “cost” is understood to also mean quality, safety, lead-time, etc.), and developing human thinking and capabilities to achieve these as part of one’s daily job. The overall objective is to create continuous flows of material and information by eliminating waste, unevenness, and unreasonableness because this is the lowest cost method of producing goods and services.

Kaizen thinking is a unique way of thinking that is learned when one participates in Toyota-style kaizen. This type of kaizen is rooted in industrial engineering (IE) methods and is practiced for the purpose of improving productivity, with a goal of reducing cost (where “cost” is understood to also mean quality, safety, lead-time, etc.), and developing human thinking and capabilities to achieve these as part of one’s daily job. The overall objective is to create continuous flows of material and information by eliminating waste, unevenness, and unreasonableness because this is the lowest cost method of producing goods and services.

Kaizen teaches that all work activities are processes and that all processes can be improved. Therefore, the basis for problem-solving is the work itself, which, of course, is directly related to the company’s costs and profits, its mission to serve customers, and well as customers’ many and varied interests. These things are connected to one another.

What does kaizen teach? It teaches a few things that we can easily grasp, and other things that cannot be easily grasped. Some of the things that can be easily grasped, usually with the aid of some sort of documentation (chart or visual) are:

- Process improvement (batch to flow)

- Simplification

- Built-in quality

- Error elimination

Things that kaizen teaches which cannot be easily grasped include:

- Developing people

- Teamwork

- Creativity

- Time consciousness (make improvements quickly, flow)

- Cost consciousness (use your brain, not money)

I find that people mistakenly think these are easy to grasp because their conception of kaizen is finite, rather than infinite.

When I am confronted with a process problem, a refer back to my kaizen training by Shingijutsu. Kaizen taught me to focus my thinking on four abnormal conditions:

- Stagnation (queues) between process steps

- Disconnections between processes (batching)

- Errors and re-work (poor quality)

- Complexity (people struggling)

Recall that in their 1996 book, Lean Thinking, James P. Womack and Daniel T. Jones originally presented Lean thinking as:

- Specify Value

- Identify the Value Stream

- Flow

- Pull

- Perfection

When confronted with abnormal conditions, I do not refer back to Lean thinking. Why? Maybe it is because I learned kaizen first. Or, more likely, it is because kaizen is a much better process for recognizing problems and making improvements than the method specified by Womack and Jones.

I do recognize that people who have not learned Toyota-style kaizen may benefit from Womack and Jones’ Lean thinking construct and make meaningful process improvements. But, the fact is, kaizen is far more powerful. Therefore, it is my hope that people who learned Lean thinking first will eagerly seek out Toyota-style kaizen experiences.

Let me explain why kaizen is far more powerful. Toyota-style kaizen is remarkable for how it develops human thinking and capabilities for improvement. With kaizen, you learn how to balance stakeholder’s interests, eliminate say-do inconsistencies, challenge your beliefs and assumptions, reduce illogical thinking, and eliminate common decision-making traps. Recognize that the origin of corporate distress is bad thinking, and Toyota-style kaizen helps leaders avoid bad thinking. Costly errors are therefore fewer in number and smaller magnitude when they do occur. Lean thinking does not teach these important things nearly as well as kaizen thinking.

While Lean thinking can be a significant improvement over conventional thinking, it is far less effective than kaizen thinking at developing people’s capability for good thinking. Good thinking leads to good decisions, whether one works on the shop floor or in the top offices. And, good decisions mean people are not harmed.

It is also worth noting that Womack and Jones’ emphasis on Lean thinking as a means for learning and developing people, and also respecting people, is a recent development. It is a revision of the original technocratic construct presented in the book Lean Thinking. Click here to learn more.

For some time now, it has been common to hear people say that Lean is a strategy for creating competitive advantage, innovation, and sustainable growth. Can Lean really do all that? It surely cannot do that without Toyota-style kaizen. Each of these commonly desired characteristics – competitive advantage, innovation, and sustainable growth – suffer large debits in the absence of kaizen. In other words, Lean, without Toyota-style kaizen, offers far more than it can possibly deliver.

So, the answer to the question, “Is Lean thinking the same as kaizen thinking?” is “No.” Lean thinking and kaizen thinking are different, and imbue people with significantly different thinking and capabilities for improvement. If you have not learned Toyota-style kaizen, you should. Focus on that.