Times have changed since the term “Lean” was first introduced to the world in 1988, 33 years ago. Back then the need for Lean was in relationship to national and corporate competitiveness, cost reduction, quality improvement, and reducing the time from order to delivery. These things remain important, but two things are emerging that are more important: human rights and the environment.

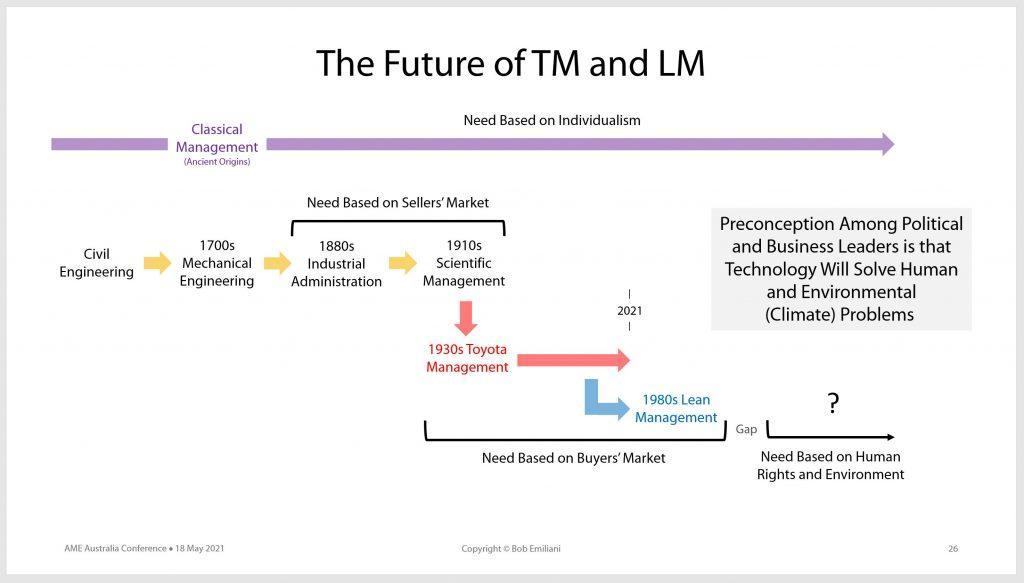

The image below is a slide from my 18 May 2021 keynote talk for the AME Australia 2021 conference. Let me explain this slide starting at the top of the image. Classical management, ancient in origin, is based on individualism. It has evolved a bit over time, but classical management is rooted in preconceptions which prevents it from evolving to meet humanity’s needs.

The first modern form of progressive management was “Scientific Management. It gave birth to the technical discipline of industrial engineering, the foundation on which Toyota’s production system is built (as well as Toyota’s overall management system which is rooted in scientific thinking and sensory perceptions). Scientific Management addressed “sellers’ markets,” wherein a company sells everything it makes (in part because of limited competition, and so producers have pricing power). A primary goal of Scientific Management, therefore, was to increase output by eliminating waste (the early 20th century definitions of waste) because that was the need (another important need was “industrial peace” — cooperation between management and labor).

Toyota’s management system was developed to serve a different kind of market — buyers’ markets — in which customers have many of choices due to the existence of a lot of competition (and producers thus lose pricing power). A derivative of TPS called “Lean” came into being and was intended as a generic version of TPS. A primary goal of TPS and Lean was to closely synchronize supply with demand, thus avoiding over- and under-production. Make only what you can sell was the need.

Where do we go from here? What is the need today and in the future? And how does Lean fit in? Look at the lower right corner of the above image. Increasingly, the need no longer relates to buyers’ markets; it relates to human rights and the environment. However, both political and business leaders see technology as the answer to nearly all the problems facing humanity. Nowhere is the management of organizations — people and processes — seen as part of the solution to current and future human needs. This is where Lean falls down hard, 33 years later. It is not present in the minds of top political and business leaders as part of the solutions to critically important human and environmental problems. Forceful action needs to be taken immediately to correct this glaring problem.

First, human rights (e.g., sections B.2 and D.7). In my view, “respect for people,” which embodies critical thinking and the right to speak truth to power, is a basic human right. But it goes further. People in the workplace want to have a greater voice and to have their voice heard and acted upon to the greatest extent possible. And they want to contribute more than just doing what they are told to do. They do not want to be forced to accept leaders traditional beliefs and untested assumptions about business and society, their illogical thinking, and the preconceptions and cognitive biases that give life to leaders’ practice of classical management and perpetuation of the status quo. Millennials (born 1981-1996), Generation Z (born 1997-2012), and Generation Alpha (born 2012-2027) face a future, unwanted, where they will likely be forced to conform to the precepts and traditions of the past, which are so obviously unsuitable for the future. Lean management can play an important role in satisfying the need for human rights in the workplace and in society.

Second, the environment. Earth has finite resources for both extraction and disposal. We must find ways to satisfy customers demand for products and services while reducing resource consumption and achieve much higher levels of recycling and reuse and much greater reductions in the amount of trash stored in landfills and incinerated. Much of this waste is the result of providing convenience to customers. But convenience, if customers actually demand it, can be satisfied in other, more innovative ways. With respect to climate change, the question is no longer “it is real?” but “what do we do about it?” and “how quickly can we do something about it?” Greenhouse gases are a byproduct (negative externality) of economic activity in a carbon-based economy. Lean management, and the human ideation that results from it, can play an important role in reducing the environmental impact of economic activity and contribute greatly to ameliorating climate change.

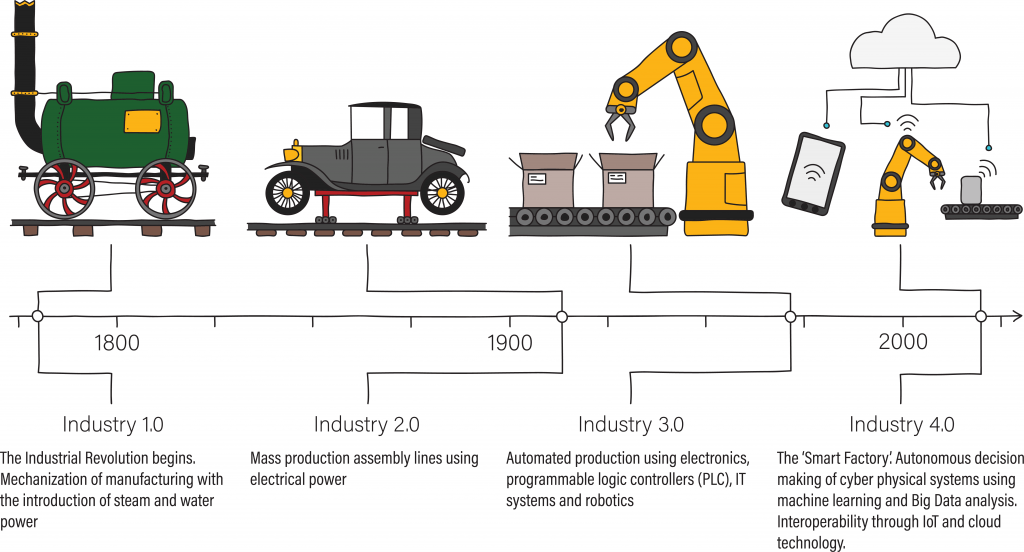

Yet this points to an even larger problem: human health (and happiness). Continued diminution of human capability and contributions in the workplace and in society increase and sustain stress and, consequently, disease. A climate that becomes less hospitable to humans also increases stress and disease. So, ultimately, Lean management can play a critically important role in improving human health and well-being, and do so alongside with emergent technological solutions which will surely be needed. The combination of Lean management and technology will provide solutions that will be better than technology alone. Yet most political and business leaders’ viewpoint remains rooted in traditions that will result in doing only half of what could be done: technology under the aegis of archaic classical management (see image below) instead of technology and Lean management (new management technology).

The easily winnable argument will, of course, be: Who needs Lean management when these four fantastic industrial revolutions, and associated technology products and services, came about under classical management?

Lean management can do much more for humanity than what it has been asked to do in the past. It should be an integral part of the solution set going forward. But, who has access to the top political and business leaders to make the case for Lean? And if one or more people in our community has access, would they be willing to make the case? If not now, then when?