What is the role of a professor in the Lean movement? Is it to mindlessly cheerlead Lean and accentuate only the positive? Or, is it to think critically, carefully analyze the product (based on experience using the product), and identify practical improvements? My involvement with Lean management has focused on doing the latter – which, of course, is what professors should do (though many don’t).

What is the role of a professor in the Lean movement? Is it to mindlessly cheerlead Lean and accentuate only the positive? Or, is it to think critically, carefully analyze the product (based on experience using the product), and identify practical improvements? My involvement with Lean management has focused on doing the latter – which, of course, is what professors should do (though many don’t).

Thinking critically about Lean bothers many Lean advocates, and so I periodically receive e-mails from well-known Lean consultants and other important members of the Lean-industrial complex who are “concerned” about me and my work. Their communication with me follows the same pattern: They start out by saying they have a lot of respect for my work, then tell me how they dislike my tone — though never challenging me on the facts I present. They suggest I am jealous of others’ success and that I think I am the only one who understands Lean. They always say that they have heard other people say the same things about me. They end by saying or implying that I would be more effective if I just fell in line with everyone else.

¯\_(ツ)_/¯

A professor’s role is to analyze the work of others, think, study, and contribute to the body of knowledge. This work necessarily functions from a negative perspective in order to make positive advancements in both knowledge and practice. The job is to identify gaps in knowledge and fill them in never-ending PDCA cycles. In my case, having decades of practical experience with TPS/Lean gives me a great advantage over other academics who possess merely book knowledge. The ultimate aim of my work is help people so that they can be more successful. By people, I mean both individuals and organizations; the people who created Lean itself and those who consume (i.e. practice) Lean.

So I point out things that cause discomfort to those with vested interests in Lean’s success. For example, the creators of Lean missed a key component of TPS for about 20 years (1988-2008), the “Respect for People” principle, as well as its interdependence with “Continuous Improvement.” They did not understand Lean leadership and its importance in Lean transformation. And they did not understand the industrial engineering basis of TPS nor its market basis (buyers’ vs. sellers’ market). These gaps are incredibly consequential as they greatly reduced people’s ability to generate successful outcomes in their organizations.

Importantly, these and other gaps have caused the Lean movement to be less successful than originally imagined — which is now widely acknowledged among Lean movement leaders in part because of the pressure that my work has put on those whose mission it is to advance Lean. I often relate my own experiences with TPS and Lean and passionately argue in favor of the practices that I learned from Shingijutsu. I speak from a position that is the combined result of first-hand knowledge and practice in an effort to correct underperformance.

I am not driven by base motivations such as jealousy or money. My role as a professor — the helping profession of teaching — differs from others, and therefore my contributions to Lean are different. Unfortunately, there remains little room in Lean world for facts and views that differ from the party line. I am an independent voice, free of conflicts of interest (which entangle nearly all others) so that I can serve the Lean community at-large. There may be no one else in Lean world who can say that.

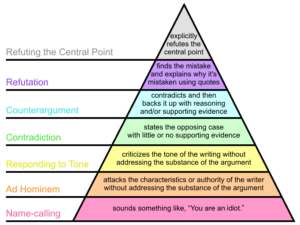

Over time, I have found that people, especially those whose incomes or personal success is based on Lean, consistently misunderstand my critiques of Lean by a wide margin and also mistakenly view them as ad hominem attacks (see image at right). But in fact, my critiques are always rooted in counterargument and refutation (top three layers of the pyramid).

Unfortunately, criticism of my work always originates in the bottom four layers of the pyramid, which does nothing to help me improve my work. Such feedback is worthless. Truly, I expect better from people who have graduated from the best schools in the world and who claim to be excellent critical thinkers, capable of formulating and defending fact-based arguments. This suggests to me that their concerns about my work are political, not factual.

To sum up, I don’t worry about what others think. If I did, there would be less progress and slower progress towards getting to the truth. That’s how professors think, and that’s what professors do.

To view my contributions to the body of Lean knowledge and practice, click here for research papers, here for books, and here for blog archive.