One of the foundations of Lean management is to think — to be a Lean thinker. That means more than thinking only about Lean and how great Lean is. It means thinking about evolving and adapting to changing times based on needs. It means changing Lean and building upon Lean if the need exists, because one day the preconceptions upon which Lean was based may no longer be valid and thus prevent needed progress in management practice.

In this post, Lean is understood to be a derivative interpretation of Toyota’s management system (TMS). Lean is the popular version of TMS. As such, the two are not the same. See “Is Lean the Same as TPS?” The differences or similarities between these two forms of modern progressive management are important relative the discussion that follows.

The question arises periodically as to what comes after Lean? This question comes either as a curiosity or thought experiment, or from someone who thinks Lean management, like a trend, has run its course and it is time for something new. Some people think Lean management is great as-is and that there is little room for improving its principles and practices. That certainly is not the case for TMS, so why would that be the case for Lean?

My view is that it is almost impossible that nothing comes after Lean management because Lean is not perfect as-is. Below are some scenarios by which Lean could be abandoned or, hopefully, substantially improved — both of which happened to 1910s Scientific Management. Scientific Management was largely abandoned by the late 1940s, but Toyota people found ways to substantially improve it, and academics from Massachusetts Institute of Technology successfully re-cast difficult-to-understand TMS as easy-to-understand Lean for popular consumption.

The scenarios are:

1) Lean (not TPS) seems to possess characteristics of a trend (more so than a fad, which is short-lived) and may be subject to a life cycle. In either case, Lean may fade away someday and be replaced by something better, or perhaps worse — the status quo of classical management.

2) As humans evolve and as we gain a better understanding of ourselves, our needs, and how we coexist with each other and the environment, Lean (or TPS) will almost certainly evolve in substantial ways to include additional principles, methods, and tools. Problem solving will evolve from two-dimensional technocratic to three-dimensional holistic (human-technical).

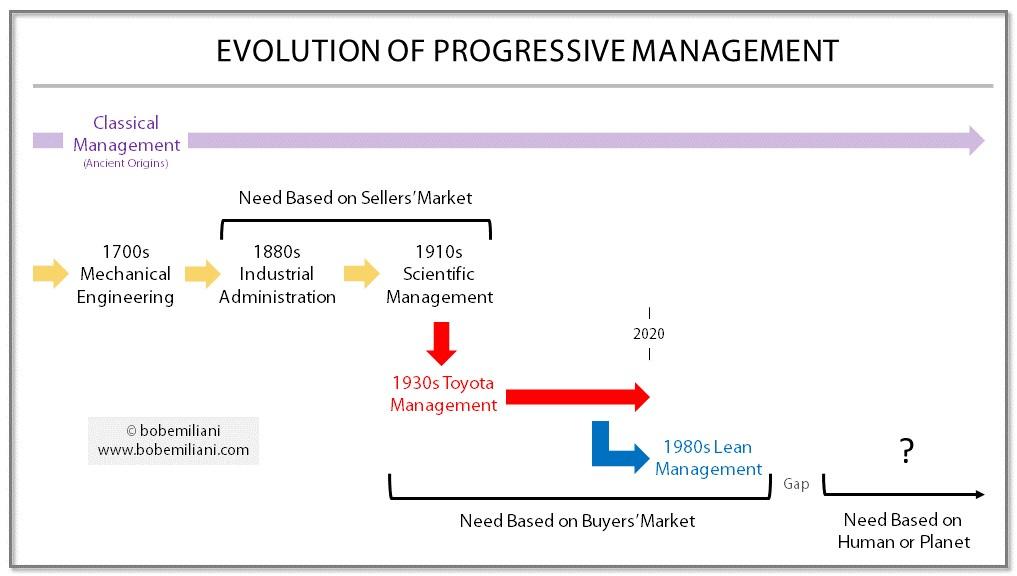

3) It seems likely that someone will lead a team that will build on the foundation of Lean (TMS) in some substantial way that reflects human needs 50 or 100 years from now that we cannot yet imagine. Scientific Management was developed for sellers’ markets, TMS for buyers’ markets (see image below). What comes after Lean may not be market-based, but human-based or planet-based. Both Scientific Management and TMS (and Lean) seek to achieve balance among competing interests. If this important concept is carried forward, market and business interests will not appreciably suffer (and might even prosper more) — though certain preconceptions will change or be abandoned, as both need some improvement.

4) Lean (and TMS) has its own preconceptions which are not timeless and are therefore subject to change. Survival depends on our ability to destroy our preconceptions. One such preconception to destroy is that nothing comes after Lean (or TMS).

Lean thinkers need to aggressively think and develop something that comes after Lean. If they do not think, Lean will not evolve and improve, as is required for changing times. Failure to do so means that Lean management is indeed a trend, which, like Scientific Management, will come to an end. Perhaps sooner than we realize.

The image below depicts the evolution of Progressive management, with archaic classical management ever-present and lurking in the background, always ready to extinguish any form of progressive management that might threaten its existence. Scientific management, and later TMS, were solutions to market-based problems that businesses faced.

Scientific management was developed to meet the need of the times from approximately 1880 through the 1930s: producer-driven sellers’ markets. In that time companies could sell everything they made and were unable to keep up with demand. So, the scientific method was applied to management practice to increase productive output. It was the start of management practice based on perceptions, rather than preconceptions.

But, over time, most markets shifted from sellers’ to buyers’. Thus came a new need to manage the business in a different way, one that was responsive to demand-driven buyers’ markets. Taiichi Ohno and numerous Toyota team members picked up where Frederick Winslow Taylor and his colleagues left off and created a management system for buyers’ markets. Their sustained effort to build on Taylor’s work is remarkable and worthy of careful study. The question is, who will follow in their footsteps to produce the next major iteration of progressive management based upon the need that exists 50 or 100 years from now?

CEOs, being a lazy bunch, are always looking for ways to create sellers’ markets and sustain the practice of archaic classical management — or, more accurately, eliminate the need for Lean progressive management. Classical management, rooted in preconceptions, is not a market-based management system. It is a privilege-based management system that serves vested interests so perfectly and completely that they see no need for progressive management.

So, what comes after Lean? Nobody knows, but four thing are for sure:

- Neither TMS or Lean are perfect

- Times change

- Needs change

- Solutions will emerge from human ingenuity

Will you be part of that, or will you remain attached to the status quo, which is your current understanding of TMS and Lean and the needs under which these solutions were created?