Leading authors and luminaries in the Agile community have, after only 19 years, begun to publicly question its de-evolution from something grand (Agile Manifesto, to improve software development) to something “misdirected, misattributed, ineffectual, and misshapen.” They are calling Agile a failing enterprise. Bravo! There is great intellectual honesty in doing that, which may lead to needed corrections, focus, or re-direction.

Lean started out as something grand — creating Lean enterprises — yet it too has become a failing enterprise. Unlike Agile’s leading authors and luminaries, I see no such intellectual honesty among leading Lean movement authors and luminaries after 32 years. What I see is business as usual. Sure, Lean will evolve in response to changing conditions (technology, processes, and the nature of management and work), principally because it must. But will it achieve was has eluded it before: wider CEO acceptance of Lean as a replacement for classical management?

Why are Agile leaders able to exhibit the courage to publicly, and bluntly, question its current state, to comprehend Agile as a failing enterprise, but Lean movement leaders, who remind us of the importance of understanding the current state and hansei, can not? Without such intellectual honesty, needed correction, focus, or re-direction are unlikely to be made and Lean’s relevancy could continue to decline. Yet I do not expect intellectual honesty to suddenly blossom because doing so seems to violate an unwritten rule among Lean movement leaders regarding admission of failure. While we are also reminded by our Lean movement leaders that failure is not failure, it is only learning, apparently failure is not learning in this case. Instead the survival plan is to just “move on” and convince people of the future potential of Lean management in a world challenged by digitization, the pandemic, the environment, and so on.

The image below succinctly summarizes an important failure. It was posted on LinkedIn on 15 September 2020, promoting the Lean Enterprise Institute’s “Virtual Lean Learning Experience 2020.” The message “Lean ≠ Mean” should have been vigorously deployed 30 years ago, and consistently thereafter, had there been awareness that progressive (Scientific) management from an earlier era (circa 1910-1940) was also then seen by CEOs as a cost cutting and get rid of people program. History’s lessons being unlearned, we receive a wise message that is now no longer relevant. Perhaps the next outdated message we will hear is how important kaizen is to Lean enterprise success.

As you may know, I have been working many years to help induce a reckoning in the Lean community, staring with the need to scientifically analyze Lean transformation failures, to comprehensive studies on why CEO resist or reject Lean management, and most recently to my Free Virtual Lean Mini-Conferences, where I pose provocative questions to challenge preconceptions about Lean management in an argument- counterargument format forces people to think, and finally my brash and indelicate “Wake the F*#! Up” message. This body work, ignored and disparaged by Lean celebrities, Lean intelligentsia, and others, assures lifetime excommunication. Their punitive sanctions, lack of bravery to publicly acknowledge the facts, and continuing desire to maintain the status quo are striking.

The Lean Enterprise Institute’s Virtual Lean Learning Experience 2020 continues on the path of ignoring the elephant in the room, which is that most CEOs (99+ percent) resist or reject Lean management. There seems to be great contentment in the oversimplification and commoditization of Lean management as it moves ever-further away from its Toyota Production System origins. It seems the survival plan for Lean management is simply to do in the future what has been done in the past. That is a great plan, not for survival, but for irrelevancy. I consider this an abdication of both intellectual leadership and social responsibility.

Given that we empirically know most CEOs resist or reject Lean management, can the statement below be taken seriously?

Lean management thinking and practice is well-positioned to fix the business turmoil caused by the coronavirus pandemic and other critical looming challenges, according to the two leadoff keynoters [Jim Womack and Jim Morgan] at yesterday’s start of the Virtual Lean Learning Experience 2020 (VLX) conference.

The common preconception is that crises are made for Lean. I contend that crises and the so-called “burning platform” are far less useful for initiating than is realized. CEOs have many options for responding to crises, and Lean has proven itself to be unappealing in that regard. Since most CEOs resist or reject Lean management, they are unlikely to use Lean to fix anything.

The intent of Lean was a better management practice to replace classical management; to create Lean enterprises. Instead, CEOs used Lean tools to augment classical management practice and have been more than satisfied with isolated Lean improvements. For 32 years, the product, Lean management, has not sold well to CEOs. Isn’t it time to do something different? If Lean management is to survive in the coming decades as something relevant, it needs more than to evolve. It needs a new intellectual foundation, one that is consistent with the times we live in and the challenges that business and society faces in the future. It is obvious that Lean management, as it is was constructed in the 1980s and 1990s, no longer fulfills that need. But to do something different requires a new and more advanced understanding of the problem.

WHERE DO WE GO FROM HERE?

There is clearly a need to backtrack and do some homework because Lean will face the same problem in the future that it could not solve in the past: that most CEOs resist or reject Lean management. The BIG mistake that people — Lean movement leaders and everyone else — made from the start is that they thought they knew how CEOs think, what CEOs want, and what CEOs cherish personally and professionally. It was a near-fatal error in terms of creating countless Lean enterprises. But there is a relatively simple solution, or at least a simple first step towards a practical solution. Before we get to that, let’s examine some even simpler solutions that are also practical.

Option 1: Accept the current state of the institution of leadership (as nearly all Lean movement authors and leaders have).

- Quit Lean

- Keep doing what you have been doing

- Improve what you have been doing under your same preconceptions

This is surely the preferred option for most people because it requires either no work or no additional work in terms of learning new things — only hope. So, either quit Lean (unlikely), keep doing what you have been doing (most likely scenario due to sunk costs), or improve what you have been doing (possible, but results are unlikely to change) — and pray for a miracle that a few more CEOs take an interest in Lean management to sustain it into the future.

Option 2: Reject the current state of the institution of leadership, gain new knowledge, and challenge your preconceptions.

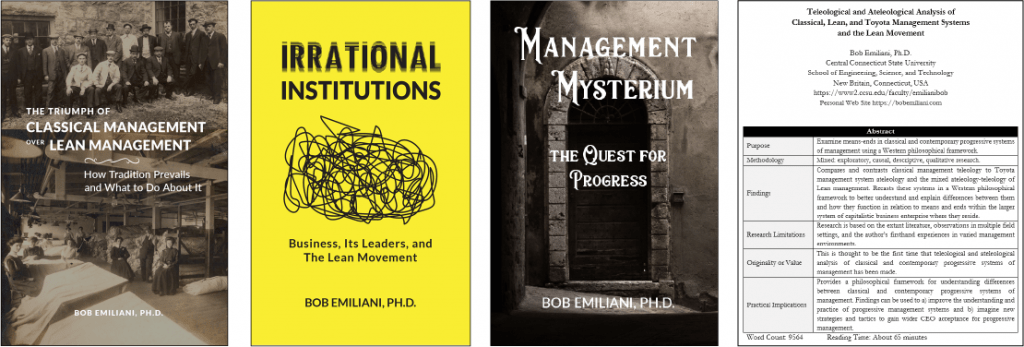

This option requires some work, reading time, and a financial investment of US$40. It requires reading 548 pages contained in three small 5.5 by 8.5 inch books (with lots of tables and images so the actual reading is less), and one 22 page research paper (free). The four works shown in the image above (click here for more information) describe the current state of the institution of leadership, the “lay of the land” of leadership (including its formation beginning some 350 years ago, and earlier) — how CEOs think, what CEOs want, and what CEOs cherish personally and professionally. These four works finally answer the century-old question: Why do CEOs resist or reject progressive (Lean) management?

The next question is one that we should all be working on based on learning from the four works I have produced: How do you get CEOs to accept Lean management as a replacement for classical management (regardless of the technological environment or the nature of work). These are your choices for solving this problem:

- Think for yourself

- Learn from others

- Learn from others and think for yourself

“Think for yourself” is very difficult given the problem at hand because it requires an enormous amount of time to do the requisite research. “Learn from others” is a better option (someone else does the research), but learning without thinking how to improve is mostly wasted time. The third choice is “learn from others and think for yourself,” followed by coming up with ideas and taking action. This is the better choice; to build on the work of others.

Read the four works to understand the current state of the institution of leadership. In these works, I offer some practical solutions, but I have struggled greatly to discover additional practical solutions. Likely you will too, even if you think really hard. Why? Perhaps because you have an engineering or scientific thinking mindset as I do, which is ill-suited, in my view, for finding solutions to the second question. But maybe you will succeed and develop a few new ideas on your own to try. I hope so.

Now, finally, we come to the simple solution, or at least a simple first step towards a practical solution:

Organizations that promote Lean, consultants, and other companies, can charge a small team people who specialize in marketing to read the four works which describe, in glorious detail, how CEOs think, what CEOs want, and what CEOs cherish personally and professionally. We will denote the CEO as the customer of Lean solely for the purpose of solving this problem. You can hire a marketing team if your company does not have one (I suggest a woman- or minority-owned business). Challenge the marketing team to think of seven ways to market Lean to CEOs based on their new understanding of the institution of leadership and the target customer. The marketing team need not concern themselves with company size since most CEOs think in remarkably similar ways. (Don’t believe me? Then read the three books and one paper). Next, have the marketing and sales teams work together to try out all seven ways, see what works and what does not, and then make adjustments (PDSA, right?).

Get the second problem — How do you get CEOs to accept Lean management as a replacement for classical management? — into the hands of creative and innovative specialists who have vastly different knowledge, cognitive abilities, interests, and goals. It is the type of challenge that marketing professionals love: figuring out how to get people interested in goods and services that are for sale in relation to customers’ needs and their peculiarities (i.e. solutions to customers’ problems). I bet they will figure out how to double the conversion rate for CEO acceptance of Lean management, a significant increase over the current low number. That would be a big achievement. Maybe the conversion rate will triple or increase five- or 10-fold. You do not know unless you try.

The marketing team that figures it out the solution to the problem “How do you get CEOs to accept Lean management as a replacement for classical management?” will enjoy the first-mover advantage and quickly grow and gain market share. Hopefully, that will then translate into greater numbers of Lean enterprises, tangible benefits for the clients, and numerous positive externalities for stakeholders (employees, customers, suppliers, investors, and communities), society, human health, and the environment.