In the last half of the 1990s, someone or a small group of people at the Lean Bureau decided to unbundle Toyota-style kaizen into various tools and sell them individually. Nearly all others soon followed their lead. With this decision, market-based or not, the Lean Bureau greatly expanded its social influence and business income, but ceded its technical authority.

Historically, top business leaders are averse to new management systems, preferring instead good old classical management. With the help of consultants, they are always happy to import some new tools from the world of progressive management, but not the entire system. The promoters of Scientific Management learned this lesson over 100 years ago, and they could not understand why their devoted efforts fell so short. Importing some Scientific Management tools destroyed the fundamental idea behind Scientific management, which was to understand the work using the then newly created industrial engineering methods so that workers increase output and earn higher pay.

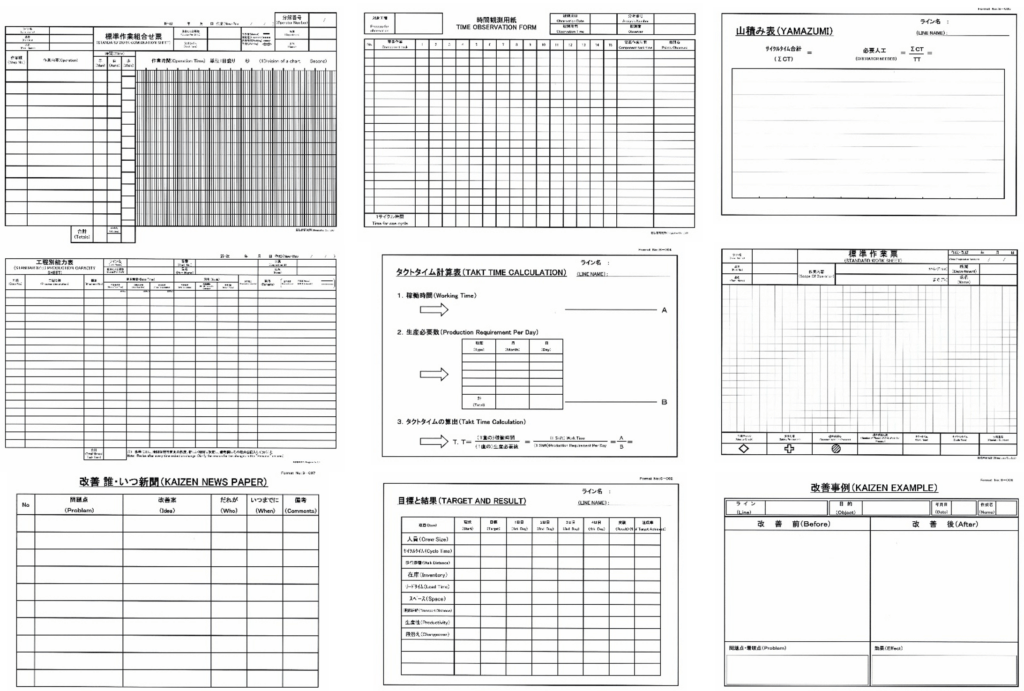

The decision to sell “Lean tools” and related training yet again destroyed the fundamental idea, this time the idea behind TPS and the Toyota Way, which was to understand the work using industrial engineering methods to improve productivity by creating flows of material and information. How many Lean professionals can calculate takt time, perform time observation with a stopwatch (and splits), create a yamazumi chart, or complete a standard work combination sheet? Who practices Moonshine? Not many, because likely all they know is 5S, value stream maps, A3 reports, gemba walks, kata, coaching, etc.

Toyota-style kaizen is a method that provides the context for using and learning so-called “Lean tools,” with the addition of human creativity, born from “Respect for People,” to simplify the work and make it easier. Unbundling Toyota-style kaizen decontextualized how the tools are used, and decontextualizing kaizen substantially reduced its power to solve problems. But what was lost in problem-solving power, it gained in creating a highly profitable bandwagon effect:

The bandwagon effect is the tendency for people to adopt certain behaviors, styles, or attitudes simply because others are doing so. More specifically, it is a cognitive bias by which public opinion or behaviours can alter due to particular actions and beliefs rallying amongst the public. It is a psychological phenomenon whereby the rate of uptake of beliefs, ideas, fads and trends increases with respect to the proportion of others who have already done so. As more people come to believe in something, others also ‘hop on the bandwagon’ regardless of the underlying evidence. Following others’ actions or beliefs can occur because of conformism or deriving information from others. Much of the influence of the bandwagon effect comes from the desire to ‘fit in’ with peers; by making similar selections as other people, this is seen as a way to gain access to a particular social group.

We will never know whose idea it was to unbundle kaizen and decontextualize it. The Lean Bureau had the chance to create a different outcome compared to Scientific Management, but they decided against doing that.

As Mark Harari said:

You can make change without progress, but you can’t make progress without change.

Unfortunately, with Lean, we see mostly “change without progress.” For that, you can thank the decision to unbundle and decontextualize Toyota-style kaizen.