A lot of people say they are Lean experts. But is there such a thing as a Lean expert? Let’s assume there is. The next question is, what does “Lean expert” mean? Is a Lean expert someone who has comprehensive knowledge and skills in some Lean methods and tools? Or, is a Lean expert someone who is capable of transforming the work? Is someone an expert because they specialize in doing a task? What if how they perform the task is wrong? Is a Lean expert someone who has contributed to the body of Lean knowledge? Does it make a difference if that contribution is made through research, or does it count only if the contribution is the result of years of hands-on practice?

When I hear someone say they are a “Lean expert,” I wonder if they know these (and other) fundamentals:

- Integrative practice of Toyota Way principles, “Continuous Improvement” and “Respect for People”

- Toyota-style kaizen and able to facilitate it

- How to do time studies and motion studies

- How to create yamazumi charts, standard work combination sheets, and process-at-a-glance charts

- How to create one-piece (material and information) flow, within and between processes

- How to build in quality (and understands why statistical sampling is the wrong way to assure quality)

- Detailed understanding of the interaction between methods/tools and human relations

- Incorporates “moonshine” into kaizen

- The three elements of Just-in-Time (hint: T-F-P)

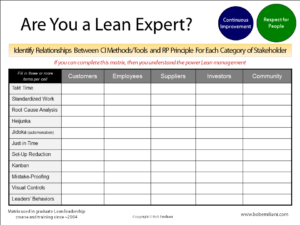

Or, do they instead mean they have deep knowledge of A3 reports, gemba walks, or value stream maps. These are not Lean in the broader sense of Lean as a management system. Knowledge of certain Lean methods and tools can be helpful for making small, localized improvements. But to substantially improve productivity and quality, reduce lead-time and cost, and engage workers and their creativity, one must have deep experience with the nine items listed. When I hear the term “Lean expert,” I also wonder if the person can complete all 55 cells contained in the above matrix.

People experienced in Lean recognize the more they know, the more they don’t know. Lean is lifelong learning; there is no end to the learning. Engaging Lean is a humbling, not elevating, experience. And because Lean is more about the thinking, mindset, and philosophy, and overcoming preconceptions, important new insights appear every day. In this context, expertise suggests a never-ending devotion to curiosity and learning

But in other contexts, expertise suggest finality. People who are incurious and done learning, but have obtain a Lean certification. Whether for an individual or company, certification suggests expert status has been attained and that the certified can slow down or stop learning. Such certifications mislead the persons certified and the companies who seek to employ those who have been certified.

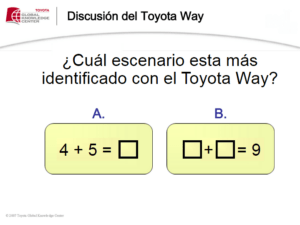

Thirty-year veterans of Lean practice consider themselves as “still in grade school.” They do not see themselves experts. Why is that? The reason is made clear in the image at right. The scenario that is more identifiable with the Toyota Way is B, not A. A suggests there is only one answer to a problem, and encapsulates a view that some experts have. B suggests that there are infinite answers to the problem; infinite ways to solve a problem, not just one best way. This is the view of someone who is a lifelong student. That’s what makes them great teachers, and thus experts, even though they will not admit it.