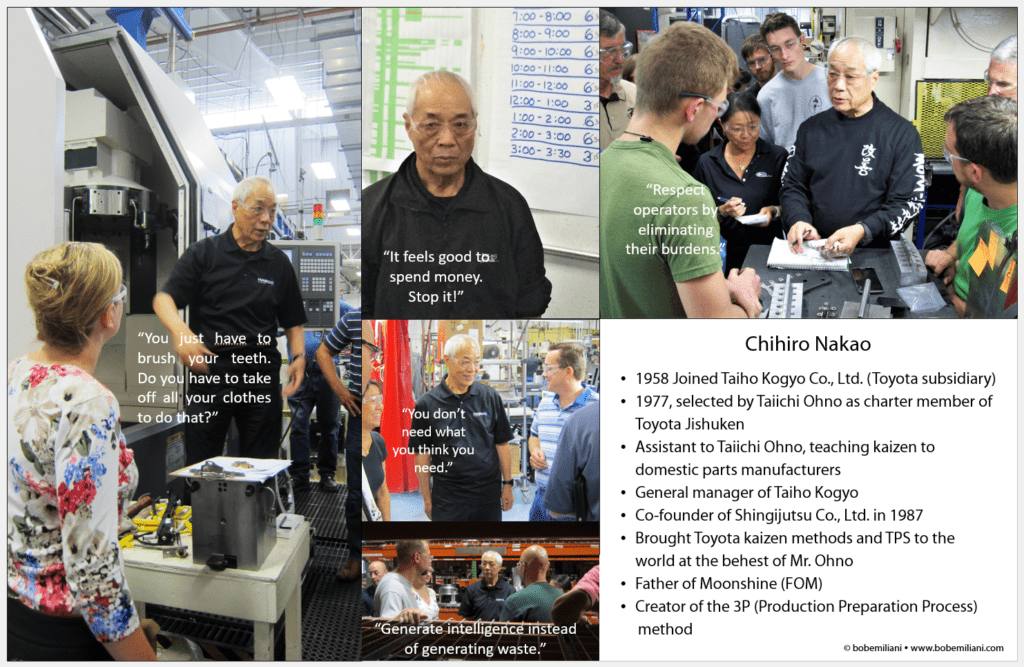

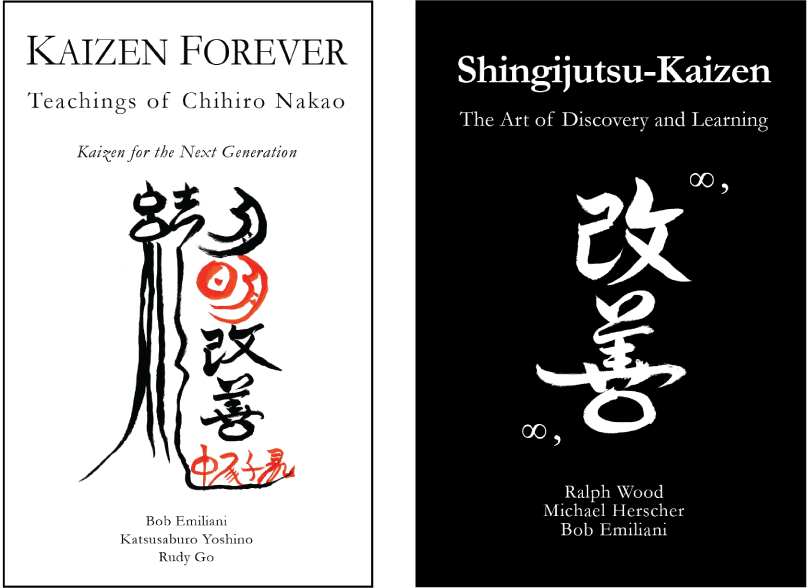

In 2014 and 2015, I had the great pleasure of spending quite a bit of time with Mr. Nakao (he was 74 years old in late 2014). It was during those years that I was working on the books shown Kaizen Forever and Shingijutsu-Kaizen. The time I spent with him was one of the most enriching experiences of my life. Re-reading the books, and writing this post, were welcome reminders of that.

One thing I learned was that no matter how smart you think you are, within five minutes of meeting Nakao-san you realize how much you still don’t know! His unique way of thinking and wide-ranging knowledge about things — and especially the connections between many things — is remarkable. How he thinks about the shop floor is similar to how a Nobel prize-winning physicist thinks about the universe: There is nothing in the world that is more interesting!

This lengthy post consists of information drawn from my personal notes. These beautiful nuggets of Mr. Nakaos’ wisdom do not appear in either of the books. I had quite a bit of fun going through my notes and recalling Mr. Nakao saying these things. Please compare what Nakao-san says to what you hear from leading Lean promoters and influencers. The difference is huge. It should prompt you to ask yourself a question: “Have I been listening to the right people all these years?” Chances are you have been led deeply astray.

- Shingijutsu literally means “new technology,” but Nakao-san’s true meaning (spirit and intent) is “shin,” always new — not new one time, but continuously new; “gi” means skill, and “jutsu” practical technique or method of using of your hands to pursue abnormalities. Always pursuing the abnormality to create the normal condition [quickly]. Doing, not talking. Action creates wisdom.

- Shingijutsu definition of kaizen: “Kai means change, fix, make new, improved attitude. Zen means the ideal state, correct, the natural way of things, good, to make better. Loosely translated it [kaizen] means continuous improvement.

- There are infinite ways to do something — new variations and combinations, many systems, many possibilities. Never give up. Always think of new ideas.

- Kaizen eyes see 1000 things needing improvement. Accepting eyes see things as they are and just accept it.

- Nakao-san says this to a kaizen team: Just look at the process. Use the stopwatch once you start to understand the process.

- An abnormality (problem) is like a splinter. It must be removed.

- One look is better than to hear about it 100 times. If you don’t see it, you will never know it. To try is the same as 100 times thinking. You will never achieve unless you try. Trying things is best. Even if you don’t think it will work, try it anyway, quickly.

- When people think of 5S as housekeeping, 5S is dead. 5S must be alive.

- When I scold people it is training to be better, no negative feelings, with a kind heart, like your mother giving you correction.

- It has to be cyclic work to establish standard work. The purpose of standard work is a gauge to tell if the shop floor is normal or not. It is like a yardstick to gauge what is going on.

- Allow operators to challenge managers.

- Increase productivity, but you can’t spend any money. So I tell them to think, and then I scold them.

- Make the book [Kaizen Forever] confusing, unclear, mysterious so that people have to read it many times to understand it, and they gain a different understanding each time they read it. [Meaning, when a book is written in a way that is easy to understand, people think they know it — but they don’t. He’s right!]. Write in a way that inspires managers to say, “This is what I want to do!” Write the soul of kaizen to leave for the next generation.

- Do not provide any answers in the book because kaizen is forever. There is no end to kaizen.

- The more you understand about kaizen, the more you feel like you are tossed into the ocean [tossed into the vastness of kaizen and the vastness of possibilities].

- Inventory gives peace of mind. You don’t need peace of mind. You need problems.

- Use precise language. Not “big” when it is in fact long. Not “shipping department.” There are no ships. It is a trucking department. Not “I have an issue.” What is an issue? You have a problem, not an issue. You cannot understand what you are doing [the process] if the language is imprecise.

- I’m not scolding, I’m converting people to Nakao’s thinking.

- He makes no excuses. So I have no reason to scold him.

- You have a tendency to think. Sometimes that works. It is better to take action.

- Coordinate measurement machines come from university professors, not engineers. “C” means computer, which kills your ability to think. CMM is worse than outsourcing. The machine is far away from the part [process]. People gravitate towards new technology. Gauges are old technology. People forget about that. This old technology must be kept alive.

- Something you could not do in 30 years you did in one day [due to kaizen].

- You must do lots of trial and error quickly. Think of it as try-try-try, no error. It is an error if you stop.

- Why do you wear safety glasses? Because you blow compressed air on the part. Find ways to get rid of the need to blow air on parts.

- You’re fired! (The specific technique is: left arm motion, forearm up to the elbow, 45 degree level sweep). Then he listened to my guidance so I rehired him 10 seconds later.

- It is not a quality clinic. It is a death certificate clinic. The part is dead when you bring defective parts to the quality clinic.

- Even in cold weather flowing water does not freeze and become stagnant. Flow keeps things fresh. Stagnant water is rotten.

- Ohno-san said: You must not do batch production. Don’t pile material up. He did not say “one piece flow.” He said flow the minimum quantity of pieces as possible. More than 2 is no good. If you ask, “Is one piece acceptable?,” Ohno-san said, “Think.” So I think zero is not acceptable. When someone said “Is this good enough?”, there was no answer from Ohno-san. A positive answer would cause people to say, “Ohno-san said it was acceptable,” and stop thinking.

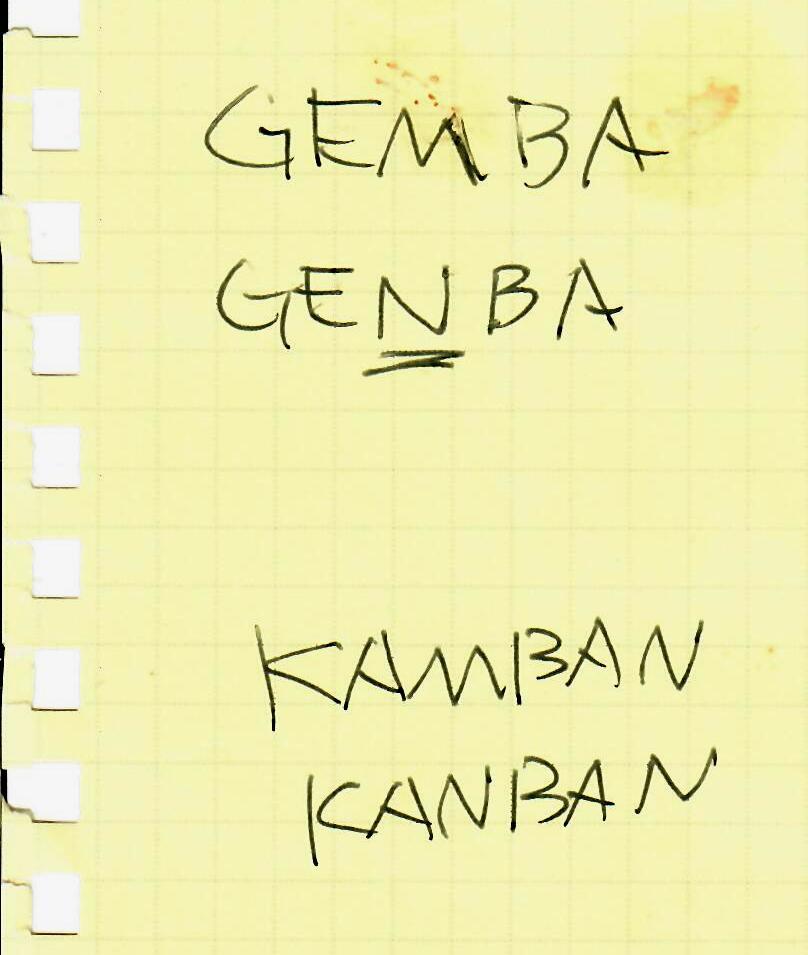

- Value stream maps became a computer map activity in the office. People don’t go to the genba (Nakao-san was very stern in saying the correct spelling is “genba,” not “gemba.” Just like it is “kanban,” not “kamban”).

- It took seven years to understand what Ohno-san was saying to me.

- Your strategy is kaizen.

- Keep trying. Think of more ideas. Make it simpler. Do it quickly.

- [What’s going on here?] What doesn’t need to move, moves. What needs to move doesn’t move.

- You pull weeds from the garden because they take nutrition from other plants. On the genba, weeds are naturally occurring. Genba weeds are muda [waste]. Pull weeds from genba. Don’t throw out the weeds. Put the weeds back in to fertilize the soil so it becomes richer. The culture of the company improves if waste pulled out is used as company fertilizer.

- The operator is the most valuable resource. They are the stars on stage. Support the stars.

- In the beginning your eyes are blind to the genba. The genba is your dojo. It is where you practice, learn, make mistakes, and grow.

- I have become sweeter and softer lately.

- The way Ohno taught was “Why did you do that?” The “why” was always a target or purpose. “What was your target?” And “For what purpose did you do this?” He made us think. I got scolded when I started looking lazy.

- The English word “action” is no good. We say kaizen.

- When you are 9 years old you have no preconceived notions. You don’t say “It’s difficult” or “It can’t be done.” You don;t worry about making yourself look good in the eyes of others. Bring your mindset back to your childhood.

- The intention is to make change [via kaizen] to make profit.

- The origin of kaizen was driven by resource constraints in Japan.

- Today, people [incorrectly] think Lean = kaizen. Things have changed [for the worse] in 30 years .

- A superhero blinds you from seeing the waste.

- Flow is the normal condition. Learn the difference between normal and abnormal condition. You can’t see abnormalities if you do work in batches.

- It is not the Toyota Production System. Wrong translation. Correct translation is Toyota Production Method.

- In the beginning you have 500 muda. After many many kaizen you still have 7 muda left. The 7 muda never go away. Even the most virtuous person still has 7 bad habits.

- The purpose of kaizen is to raise the skill level of cost reduction [total cost, not unit cost].

- Do you eat a lot just because it is cheaper?

- When you have an itch on your foot, you don’t scratch it through the sole of your shoe. You take your shoe off to scratch it and probably take your sock off to pinpoint the abnormal condition.

- Sitting around does not add value, unless it is wine.

- Inspection is not value-added due to no change in physical shape.

- Not Just-innnnnn-Time. It is Just in-Time.”In” is very short. Not “innnnnn.”

- With a pull system you can see abnormalities immediately.

- Continuous kaizen is the power of Toyota Seisan Hoshiki [Toyota Production Method].

- Baseball managers must be on the field during the game. Managers in business manage away from the field [genba]. Managers must manage in real-time through observation, not reports.

- Do it [kaizen] now. Have the intention to get it done today. It can be poorly done; you can correct it later. The point is to make progress.

- No conference room kaizen. Always go to the genba. Observe the actual work. The genba is the truth. Value stream maps are not the truth.

- American sensi are soft.

- It is wrong for operators to do deburring. Focus on burr. Why does burr occur? No burr means no need to deburr.

- I went to the plant yesterday and everything is so bad. I went crazy. That is why I am stern with you.

- Toyota industrial engineering is FAST industrial engineering for [total] cost reduction.

- You cannot spend 15 minutes on measurement. You must do quick-check with a gauge.

- Don’t think of one or two ways to correct the abnormality. Think of seven ways and try out all seven ways. That way you learn more.

- Books are information frozen in time. You must evolve your thinking and methods.

- Don’t compare before and after kaizen. Think about the next kaizen. Find new waste. New kaizen is immediately old kaizen.

- It is a big misunderstanding to think this way of thinking is only for engineers and for operators. Management lessons from the shop need to be applied everywhere.

- Design for complexity [complex process] is easy. Design for simplicity is complex [hard].

- Operator’s time is more valuable than manager’s time.

- You think, “It’s not that easy.” But you find a way.

- Try it again, even if you fail 100 times.

- Think of the ways that one person can do it.

- At home, you don’t use your computer to find where a cup or a plate is [but you do that at work to find tools].

- You wash your face every morning. You don’t wait 10 days to wash your face.

- Everyone uses similar machines. It’s how you use the machines that makes the difference. Find the professional way to turn or mill.

- Don’t hold on to old ways.

- You must have more confidence in yourself. Don’t be afraid of making changes.

- You have to do 100% quality check for the customer to trust you.

- Teachers who teach inspection statistics is no good.

- Don’t believe everything you think.

- Kaizen is to generate ideas, intelligence, ingenuity.

- Wasting operator’s time is wasting their life.

- Get rid of tooling so you can think of new ideas.

- Deming award and Shingo prize turn into regulation and move away from the original purpose.

- Machine tool representatives look nice, dress well, speak well, and they find ways to take away your money. Don’t get tricked.

- You should struggle. That leads to creativity.

- You think you understand something. 1+1=2. But why does 1+1=2?

- People get upset when I tell them to do the opposite of what they are used to doing.

- Learn the basics and apply it to action. Learn and learn it again, and you will succeed.

- Who is crazy? Common sense [old way of thinking] people or kaizen people?

Read the books Kaizen Forever and Shingijutsu-Kaizen to learn what you have been missing.