In classical management, waste is a feature, not a bug. It is only within the very narrow realm of Toyota’s management system and Lean management that waste is bug. This sets up a cognitive dissonance that Lean people have difficulty resolving. It comes from the inability to resolve the distinction between business (money-making, property) and industry (making things, customer satisfaction). Executives and regular employees spend their days working on vastly different problems, often in conflict with one another.

If you are concerned about making things, you care about waste, unevenness, and unreasonableness. You care about continuous improvement, respect for people, PDCA, and root cause analysis. You care about these things because producing goods and services is hard work and fraught with myriad difficulties that you would rather not encounter time and time again. Whether you realize it or not, your efforts are directed to closing the problem-solving gap between business (money-making, property) and industry (making things, customer satisfaction). But, you are destined to fail because bottom-up change for the better is crushed by top down corporate strategies and ever-changing directives. (This does not mean you should stop trying.)

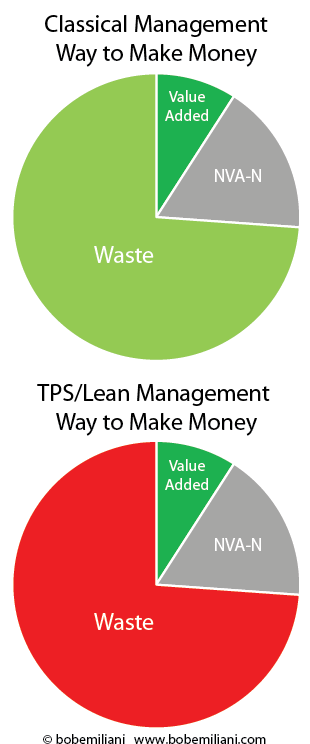

If you are concerned with money-making, as boards of directors, CEOs, and executive teams are, waste is seen as something to put to use for the purpose of efficiently making money. Given that is their main concern, the inefficiency caused by waste in making things is a small, if not insignificant concern. Any concern that CEOs have about inefficient processes for making things and the application of Lean tools is more for the purpose of emulating peer companies, to be seen as keeping up with the times, than making tangible improvements to processes that result in financial gains. What else can explain so little actual improvement across the vast number of companies, large and small, in the 30 years since Lean was introduced?

Take, for example, the productive capacity of a manufacturing or service company. This subject is of great interest to operations people and so they spend much time talking about Little’s law, calculating capacity, bottlenecks, and so on. But from the CEOs perspective, capacity is interesting for different reasons. Withholding output can be beneficial in terms of prices. There are times when underutilizing capacity is beneficial because it generates higher profits.

What about excess capacity? Should CEOs keep it or get rid of it? From the CEOs perspective, eliminating excess capacity might not be a good idea because it will reduce the value of the business (the property) and its credit-worthiness. Excess capacity has value (plant, property, and equipment) and can be borrowed against, and the borrowed money can be put to a number of different uses to satisfy the interests of investors (e.g. share buy-backs, stock dividends, acquisitions, etc.). CEOs can use capacity to throttle production up and down to achieve desired pecuniary or strategic outcomes as such interests play out over the duration of business cycles. There is no need to eliminate waste. But, if such a need arises, it is handled within the traditions of classical management (which I named as the “CEOs Wealth Creation Playbook“).

From a pecuniary perspective, waste has great value in classical management. Only a fool would try to match supply with demand, as this limits what one can do with one’s property (the company) to achieve desired pecuniary objectives. This is something that TPS and Lean people simply do not understand, and likely prefer to ignore. Yet it explains why there is little demand among CEOs for Lean transformation.

So how do you convince boards of directors, CEOs, and executive teams that the gap between business (money-making, property) and industry (making things, customer satisfaction) should be narrowed? The first step, largely ignored by Lean movement leaders and followers alike, is to understand the mind of executives and owners and the problems that they are tasked with working on. Taiichi Ohno is reported to have said this to a subordinate who was facing resistance to TPS by the president of a company that supplied Toyota:

“The president must be showing resistance because of his own convictions. There’s nothing wrong with that. However, it is wrong for you to make a judgment without learning his reasons. He must have his own strong beliefs and logics toward how his company should be run. Instead of convincing him of your idea, learn from such an unbreakable dedication to his own principles.” – The Toyota Mindset: The Ten Commandments of Taiichi Ohno, Yoshihito Wakamatsu, Enna Products Co., 2009, p. 158

It is so important for all Lean people follow up on Ohno-san’s important words by taking the time to learn executive’s unbreakable dedication to classical management. Please read my book, The Triumph of Classical Management Over Lean Management: How Tradition Prevails and What to Do About It to learn about classical management and the institution of business leadership. It will be eye-opening, and it will surely generate new pathways for expanding the practice of Lean management.

“Nothing is more comfortable than not having to think.” – Simone Weil