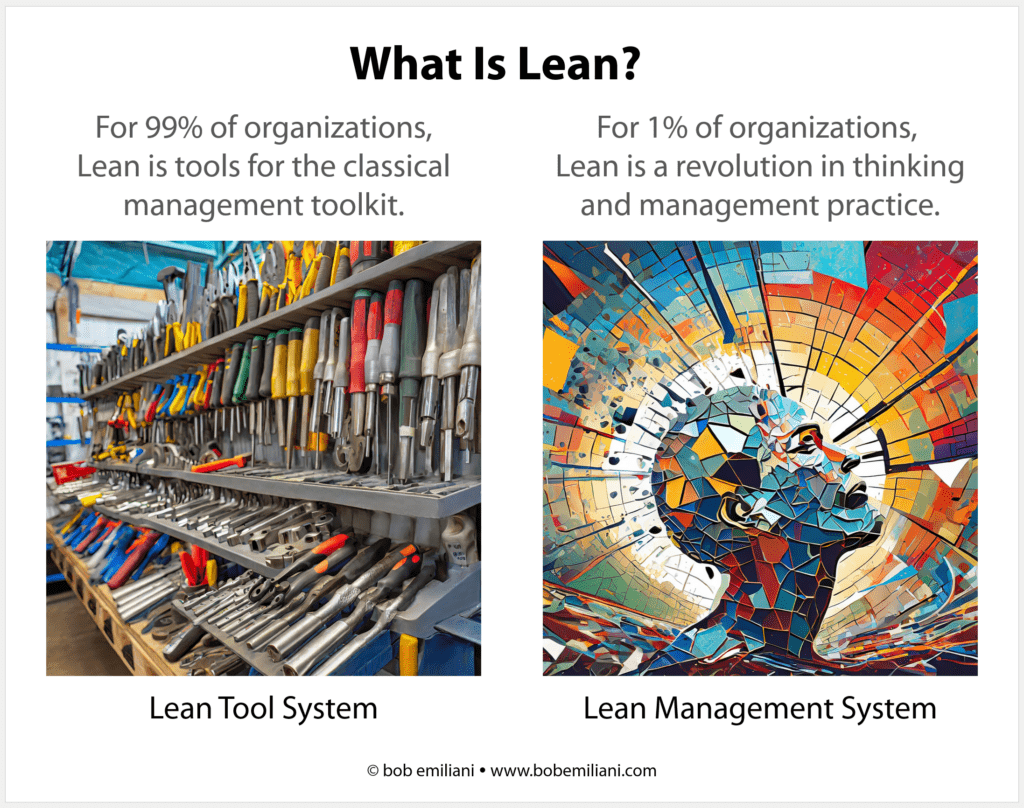

The term “Lean” started out in 1988 as “Lean production.” Then around 2007 there was a switch to “Lean management” and soon followed by “Lean management system.” But if we want to strive for accuracy in describing what has actually happened to the term “Lean” over the last 35 years — if we want to describe what Lean is today and has been for quite some time — we would call it the “Lean Tool System.”

Of course, it doesn’t really matter if the numbers in the above image are 99 and 1 or 95 and 5. The reduction of a progressive system of management to a system of tools is a predictable outcome if one studies the history of progressive management.

The mere adding of tools to an organization’s already large toolkit for employees to use to solve day-to-day problems is a sure sign there has been no revolution in thinking among top leaders and that classical management still rules.

Many people make the rationalization that some progress is better than no progress. That may be true, but in believing that they accept the situation as-is, and, worse, they show no interest in understanding the causes that limit progress — in this case why Lean management is largely limited to the use of Lean tools by workers.

Accepting the situation as-is means no continuous improvement. No continuous improvement is not the lesson to be learned from Lean management. No scientific thinking about cause-and-effect is another lesson not to be learned from Lean management.

It is worth noting that classically managed businesses don’t really need Lean tools. They still run into big business problems frequently and solve them the old fashioned way using the trusted, traditional CEO playbook.