The leaders of organizations adopt Lean management in the hope of achieving desirable outcomes such as higher quality, shorter lead-times, lower costs, and so on. In most cases, cost reduction is a major objective and is of particular interest to senior managers. Yet, the magnitude of cost reduction achieved usually ends up being far less than they anticipated.

When people’s Lean efforts fail to achieve the desired cost savings, Lean management is typically abandoned and can therefore be said to have failed. The inability to reduce costs is the result of a Lean transformation process problem. Specifically, a major defect in the process: a lack of kaizen. Not just any kaizen, but a lack of Toyota-style kaizen.

The core of Toyota’s production system is kaizen. The core of Lean — an interpretation of TPS made by researchers at Massachusetts Institute of Technology — is not kaizen. The core of Lean is value stream maps or A3 reports or something else. But it is not Toyota-style kaizen. Therefore, one would expect the vast majority of Lean transformations to result in less cost reduction than expected and eventually fail.

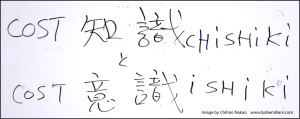

Before you can reduce costs, you must first understand what costs are and also what non-cost costs are. This is nearly impossible to understand given people’s reliance on computers, spreadsheets, and calculations to inform their thinking about costs. Non-cost costs are not even considered. As a result, neither are truly understood – not by senior managers and definitely not by the chief financial officer.

Toyota-style kaizen teaches managers and employees to understand what are costs and non-cost costs. If an organization does not practice Toyota-style kaizen, then these people will not learn what are costs and non-cost costs. As a result, they will have difficulty reducing costs. If there is no kaizen, or bad kaizen, then there will be little in the way of cost reduction. It will not be long before Lean is seen by all as just another management initiative that failed.

And, organizations that do not practice Toyota-style kaizen will not generate cost-awareness. Knowledge of cost is incomplete without cost awareness.

And, organizations that do not practice Toyota-style kaizen will not generate cost-awareness. Knowledge of cost is incomplete without cost awareness.

Most organizations do not practice Toyota-style kaizen. They practice weak, derivative forms of kaizen that have little impact on costs or other important parameters. People look busy and look like they are making meaningful process improvements, but the fancy talk and the colorful charts are mere decorations intended to impress company leaders.

This is unfortunate because employees have good intentions and put a quite a bit of effort into making improvements. They want their efforts to yield tangible results, but in most cases they have a only slightly improved process and have not reduced costs. Non-cost-costs are largely untouched, and cost awareness is not developed.

Toyota-style kaizen means to persevere in the face of adversity with an intense hunger to survive. It means learning to think like a craftsman, using mostly your own ingenuity and little in the way of resources. If you don’t have expensive equipment or other significant resources at your disposal, then you have to think creatively about how to quickly design and execute the process.

The summer after graduating high school in 1976, I undertook the challenging task of designing and building road racing bicycle frames. I had little money, most of which went to buying the tubes and detail fittings. I could afford only one power tool: an electric hand drill. All other tools were hand tools: hacksaw, files, tube cutter, C-clamps, hammer, tape measure, ruler, and so on. No lathe, no milling machine, no drill press, no jig bore, no belt sander, and no band saw.

The summer after graduating high school in 1976, I undertook the challenging task of designing and building road racing bicycle frames. I had little money, most of which went to buying the tubes and detail fittings. I could afford only one power tool: an electric hand drill. All other tools were hand tools: hacksaw, files, tube cutter, C-clamps, hammer, tape measure, ruler, and so on. No lathe, no milling machine, no drill press, no jig bore, no belt sander, and no band saw.

I had to figure out how to manufacture a quality product that functioned correctly on the road for decades using only hand tools in a space of less than 100 square feet. Using my ingenuity, I devised methods to finish the detail fittings, hand mitre the tubes, slot the tubes, hold the tubes while brazing, and so on. Then, I improved my processes as I proceeded to build additional bicycle frames in the following months and years – with no expensive new resources.

Toyota-style kaizen means to improve a complicated process by making it vastly more simple, much in the same way that I manufactured bicycle frames – a low-cost, far less capital-intensive method, where technology is used only when it is clearly necessary. And all improvements must result in improved material and information flow.

I hope this helps give you an idea of the mindset, spirit, and overarching objectives of Toyota-style kaizen. That is the approach you should be taking. The result, among many other great things, will be cost reduction.